Simulation Process Data Management (SPDM) in HPC

The Rescale platform enables engineers and scientists to leverage the aggregate knowledge generated from simulation data to better design the next generation of products.

Benefits of SPDM in HPC

Accelerating Innovation

Grow your enterprise by entering the new paradigm of cloud technology.

Faster Time to Market

Shorten development time, reduce prototyping and improve product quality.

Enterprise Integration and Collaboration

Accelerate communication, file sharing and project completion across the enterprise.

Capture Ongoing Value From Your Simulation Data

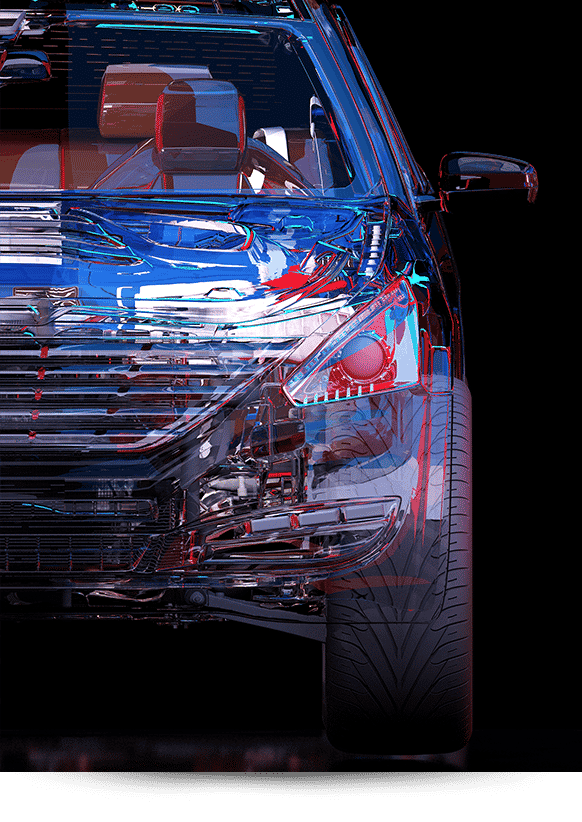

The age-old design process is well known: take requirements, create conceptual designs, select one, begin preliminary and detailed design, then validate. In the modern age, simulation is carried out at each of these steps, building mountains of raw output data. This data can remain stagnant–or it can be continuously mined and converted into actionable knowledge and business intelligence, thus accelerating and improving the next iteration of products.

Enabling users to perform Simulation Process Data Management (SPDM) is a core tenant of the ScaleX platform philosophy. The way it is built reflects this: a web-based platform, connecting data in the cloud and on-premise to massive parallelizable compute architecture. This allows users to retrieve previous simulation data, track the configurations and metadata surrounding it, and re-apply it to the current task, saving time and mitigating long-term product risk.

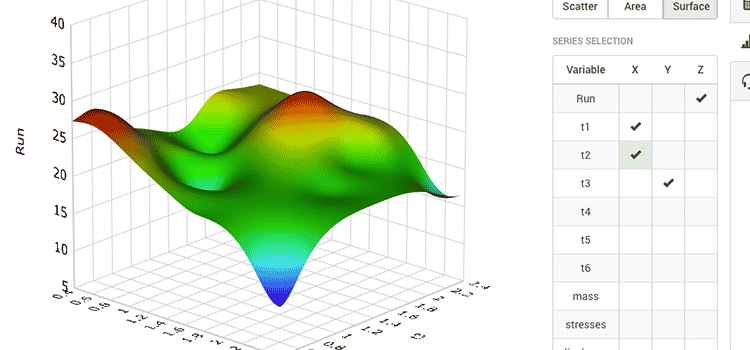

The Rescale ScaleX platform enables users to:

Mutlticloud

Store, retrieve, and leverage simulation output data in the cloud and on-premise.

Easily Manage Jobs

Track metadata, load cases and requirements.

Flexibility

Adjust and relaunch older simulation jobs with ease.